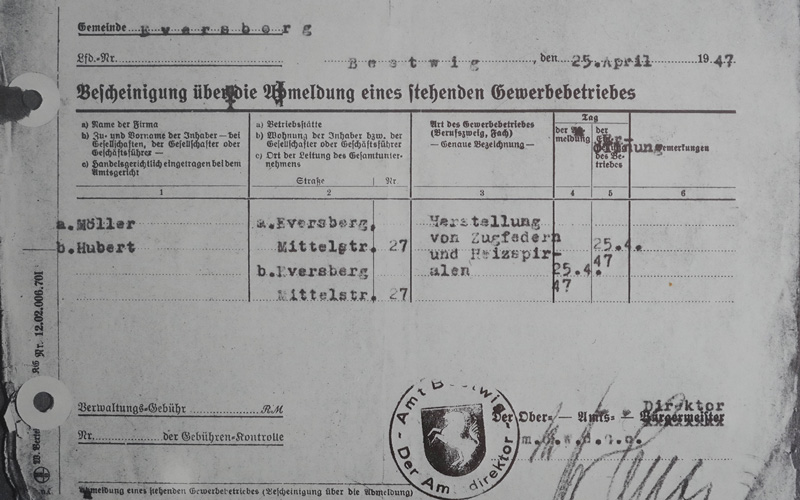

Products: metal spiral beads to put into pieces of laundry as a replacement for elastic band; electric irons and waffle makers

Philosophy

We have been working in the metal and plastics industry as an independent midsize family business for more than 70 years.

drapery wand with steel core

leave the plant

live

innovation

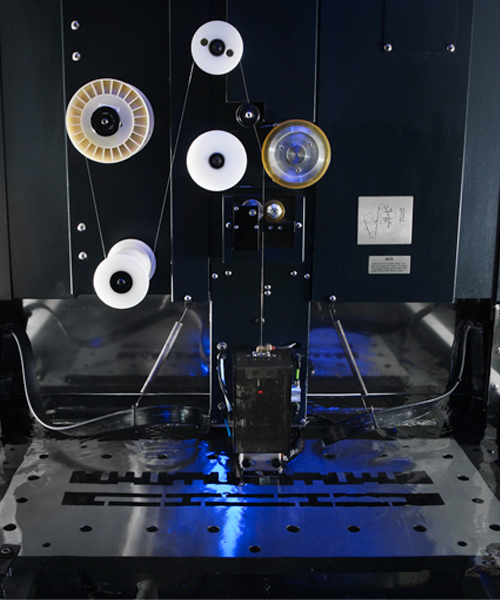

plastics processing plant; continuous

expansion of the extrusion capacities

Competence and our pleasure in innovation have made us become a sought-after system provider. We fulfill our customers’ desires with flexibility and diversity by this and develop economical solutions together.

Möller Polska in Bydgoszcz, Poland

With a high level of commitment and qualification the MÖLLER team works out perfectly fitting solutions.

From the engineering design department to the tooling shop up to the material mixing unit we work autarchically and can guarantee highest levels of quality, flexibility and quickness by this.

To enable an economical production we make use of state-of-the-art computerized extrusion lines as well as of automated production engineering.

company OOO Möller in Moscow, Russia

the product innovation LIGNODUR®

terrafina floor board systems

As an internationally oriented company with approximately 140 staff members in the heart of the area “Hochsauerlandkreis” we develop and produce technical accessories for the interior decoration business (curtain systems), products for the packaging industry, floor boards and screens of the brand terrafina®, indoor window sills of the system LIGNODUR®, plastic frames for the clean air filter business as well as special profiles for all kinds of technical applications.

Material diversity

In addition to the self-developed composite material LIGNODUR® Möller processes, also in coextrusion, unplasticised and plasticised PVC, polycarbonate, polystyrene, ABS (plastics) and metal.